Bldc Motor Hall Sensor

Bldc Motor Hall Sensor - Whenever the rotor magnetic poles pass near the hall sensors, they give a high or low signal, indicating the n or s pole is passing near the sensors. Web most bldc motors incorporate three hall sensors which are embedded into the stator. Web bldc motor needs electronic commutation, in which based on rotor position drive circuit energize stator winding. The sensors need to be fixed relative to the motor rotation and exposed to a series of magnetic poles that change in concert with the rotation of the motor. Thus bldc demands position sensing. To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors.

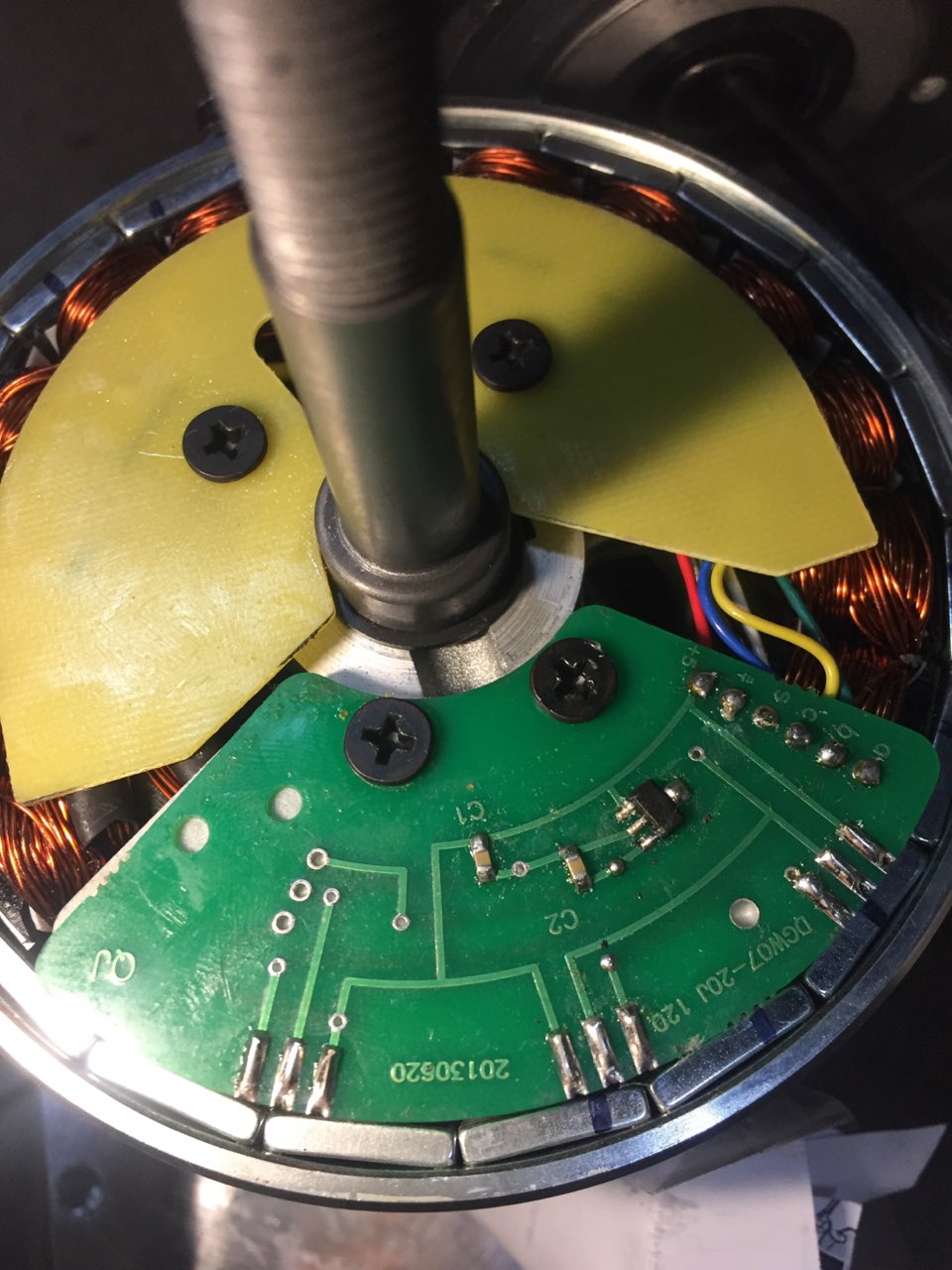

Web bldc motor needs electronic commutation, in which based on rotor position drive circuit energize stator winding. Hall effect sensors are embedded on motor stator works on hall effect; The incremental sensors, the three hall effect sensor, and the resolver. The application meets the following performance specifications: Web most bldc motors incorporate three hall sensors which are embedded into the stator.

Hervorragend Beständig Staude hall sensor in bldc motor Verwelkt

Web a digital hall effect sensor (also called buffered hall effect sensor) detects the strength of the currently present magnetic field, and has a single output wire with two possible output states: The arrow represents the magnetic field of the rotor while the coil windings (a,b,c) represents the stator. Whenever the rotor magnetic poles pass near the hall sensors, they.

BLDC brushless DC sensored motor 80100 outrunner CA80 30 70V 8092 70KV

Three common types of position sensors are used: To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors. Web most bldc motors incorporate three hall sensors which are embedded into the stator. Based on the combination.

brushless dc motor 3 phase BLDC Hall sensor problem Electrical

Each sensor generates low and high signals whenever the rotor poles pass near to it. Web the most common way to control a bldc motor is to use hall sensors to determine the rotor position. Whenever the rotor magnetic poles pass near the hall sensors, they give a high or low signal, indicating the n or s pole is passing.

Electric Bike Controllers Which One to Choose? Power Watcher

Based on the combination of these three hall sensor signals, the Three common types of position sensors are used: The control system senses the rotor position and the proper voltage pattern is applied to the motor. Each sensor generates low and high signals whenever the rotor poles pass near to it. The exact commutation sequence to the stator winding can.

HUMSER BLDC Hub Motor Hall Sensor at Rs 550/piece in Ludhiana ID

The arrow represents the magnetic field of the rotor while the coil windings (a,b,c) represents the stator. The application meets the following performance specifications: Web pole pair bldc motor with hall sensors (h0, h1, h2). Web in a bldc motor, feedback is achieved using multiple feedback sensors. Web bldc motor needs electronic commutation, in which based on rotor position drive.

Bldc Motor Hall Sensor - Web most bldc motors incorporate three hall sensors which are embedded into the stator. Carolus andrews, manny soltero, mekre mesganaw. Each sensor generates low and high signals whenever the rotor poles pass near to it. Web in a bldc motor, feedback is achieved using multiple feedback sensors. Web the most common way to control a bldc motor is to use hall sensors to determine the rotor position. To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors.

Carolus andrews, manny soltero, mekre mesganaw. To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors. Hall effect sensors are embedded on motor stator works on hall effect; Web in a bldc motor, feedback is achieved using multiple feedback sensors. Web pole pair bldc motor with hall sensors (h0, h1, h2).

Carolus Andrews, Manny Soltero, Mekre Mesganaw.

Rotor position can be known by using various sensors like hall sensor. Hall effect sensors are embedded on motor stator works on hall effect; Web the hd motors do not have hall sensors, so it's necessary to mount them to the exterior of the motor. The exact commutation sequence to the stator winding can be determined based on the combination of these three sensor’s response.

Three Common Types Of Position Sensors Are Used:

Web velocity feedback can be derived from the position data, eliminating a separate velocity transducer for the speed control loop. Web pole pair bldc motor with hall sensors (h0, h1, h2). The incremental sensors, the three hall effect sensor, and the resolver. Based on the combination of these three hall sensor signals, the

Web Most Bldc Motors Incorporate Three Hall Sensors Which Are Embedded Into The Stator.

The arrow represents the magnetic field of the rotor while the coil windings (a,b,c) represents the stator. Web a digital hall effect sensor (also called buffered hall effect sensor) detects the strength of the currently present magnetic field, and has a single output wire with two possible output states: The control system senses the rotor position and the proper voltage pattern is applied to the motor. Web the most common way to control a bldc motor is to use hall sensors to determine the rotor position.

The Application Meets The Following Performance Specifications:

Each sensor generates low and high signals whenever the rotor poles pass near to it. The most commonly used sensors are hall sensors and optical encoders. Whenever the rotor magnetic poles pass near the hall sensors, they give a high or low signal, indicating the n or s pole is passing near the sensors. The sensors need to be fixed relative to the motor rotation and exposed to a series of magnetic poles that change in concert with the rotation of the motor.